1. Catalysis Development

Catalytic transformations will eventually be necessary to move to a more sustainable plastic economy. Our aim is to develop fully organic catalyst to be implemented in industrially relevant processes. In this sense our mission is to design catalysts but always considering their scalability.

2. Sustainable Polymers

While traditionally plastics have been designed for performance and durability, the current non-sustainable scenario is fueling the implementation of more sustainable polymers. Our group intends to design new polymers with not only competitive mechanical properties but also considering their end-of-life assessment. To do so we investigate not only the use of monomers from renewable sources but also from plastic waste.

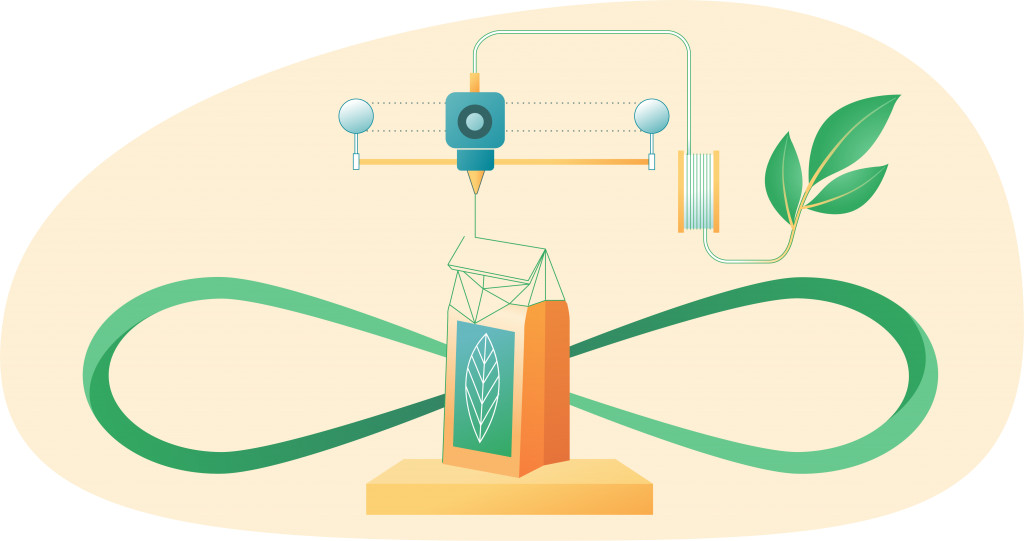

3. Additive Manufacturing

The use of additive manufacturing is revolutionizing the manner that plastics could be processed and transformed. In spite of the great promise of additive manufacturing as an advanced form of future manufacturing, there are still fundamental challenges with respect to sustainability that need to be addressed. Some of the material needs for additive manufacturing include sustainable sources of printing inks, resins, and filaments, as well as pathways for polymer recycling, upcycling, and chemical circularity.

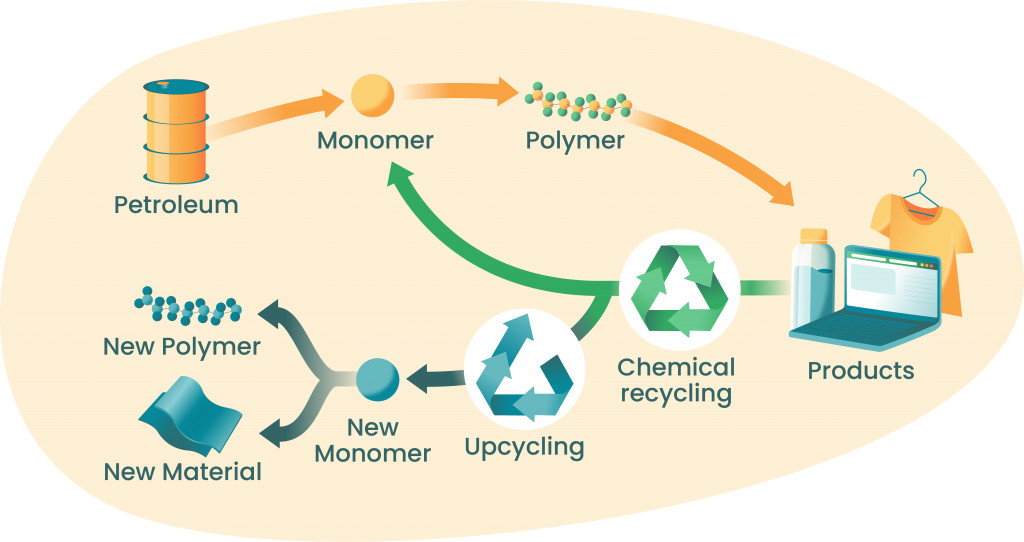

4. Chemical Recycling

The vast majority of commodity plastics do not degrade and less than 20% of post-consumer plastic waste is recycled mostly for energy recovery or by mechanical recycling in lower quality products. In our group we exploit the chemical recycling of plastics as 1) it offers an opportunity to revert plastics back to monomers for repolymerization and 2) to transform plastics as a source to produce added value monomers for the plastic industry.